Structural Health Monitoring

Geocomp conducts structural health monitoring to provide structural life extension for critical infrastructure. This includes assessing the safety and reliability of infrastructure systems by detecting damage before it reaches a critical state and assessing remaining service life through fatigue analysis. Key risk indicators can be monitored to optimize the operational and maintenance activities of complex structures.

Our real-time monitoring programs provide critical early detection data that can help guide design modifications and structural management systems. We provide integrated data and knowledge about actual structural performance to help our clients make informed decisions to manage their assets.

Our Services

› Load Rating

Load Rating

Having accurate and up to date fact-based operating load ratings for bridges allows for accurate postings and for structures to function as they were intended, facilitating transport of goods vital to our economy as well as emergency services. Load ratings are also important to meet inspection and reporting requirements to secure and maintain safety and funding.

Load Rating is a measure of bridge live load capacity. The AASHTO Manual for Bridge Evaluation defines both an Inventory Rating, the loads that can safely be utilized on the bridge for an indefinite period of time and the Operating Rating which is the maximum permissible live load that can be placed on the bridge. These may be established by visual inspections, but a more reliable and usually less conservative approach is with load proof testing. By measuring strains on primary structural elements during load proof testing, Geocomp can assist consulting engineers and owners in obtaining more accurate load ratings for structures.

› Life Extension

Life Extension

Current economic conditions and results of decreased traveling have caused a shortfall in gas tax and toll funding. Funding rehabilitation and repairs on existing structures are often much less expensive than building a new structure. Monitoring the structure for deficiencies in load capacity as well as for on-going signs of deterioration allow for real-time or near real-time repair and maintenance decisions to be made optimizing limited funding and helping to ensure public safety. With in-service monitoring and directed rehabilitation, many deficient bridges can be returned to full load rating at relatively low cost.

› Adjacent Construction Monitoring

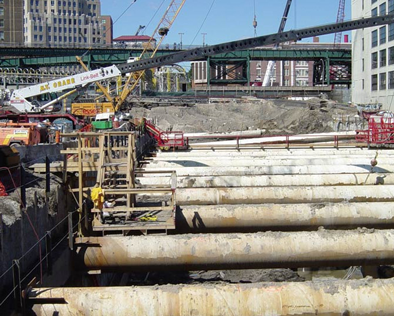

Adjacent Construction Monitoring

Construction adjacent to deteriorating or critical structures can wreak havoc on those existing structures, such as bridges, historic sites, medical facilities, laboratories, concert halls and more. These structures may be potentially impacted by vibrations emanating from construction activities such as demolition, compaction, excavation, blasting, pile-driving, and operating heavy equipment. Managing these risks using real-time monitoring helps avoid remediation and litigation and can produce significant cost savings and reduce delays.

› New Bridge Construction and Lifetime Monitoring

New Bridge Construction and Lifetime Monitoring

Providing critical information to engineers and owners throughout the life of a structure can be used to make informed maintenance and asset management decisions as well as mitigate risks to a bridge. Signature structures are now being asked to maintain service lives of up to and sometimes exceeding 100 years. Geocomp's iSite®-Bridge world class structural monitoring software platform collects and manages several gigabytes of new data each day to assess bridge performance in real time, including graphical display of 1000s of measurements, live calculations, and reports. Intelligent data reduction algorithms immediately show the effects of unusual loads and cumulative performance. Our systems can consist of high-speed data acquisition units (iSiteHS), data loggers for strain and other sensor data, as well as fiber optic interrogators and GPS receivers. All data are integrated into a central server and time synchronized to within 3 milliseconds. Short and long term behavior can be seen from easy to read statistical summaries, data analysis reports and measurement correlations. The collected data are disseminated in a closed loop cyber-secured network that can only be reached via user authentication.

› Root Cause Analysis

Root Cause Analysis

Cracking, shifting, torsion - when your structure is not behaving as anticipated, it is imperative to figure out the root cause in order to implement remediation and repairs. Geocomp's team of SHM experts can help determine whether thermal loads, frozen bearings and joints, impacts/strikes, or deterioration of materials is causing observed problems with your structure. Through use of strain, temperature, tilt, vibrations, and other synchronized sensors and testing, Geocomp will help you determine the root cause of your issues and can monitor the remediation process to help ensure that the cause has been eliminated.

› Accelerated Bridge Construction & Bridge Moves

Accelerated Bridge Construction & Bridge Moves

Slide-in bridge construction during ABC and other bridge moves require precision and accuracy for successful implementation and to help ensure safety. Geocomp's sensors and software provide real-time monitoring of key indicators to effectively and efficiently accomplish bridge moves without compromising safety.

› Moveable Bridges and Wind Power Structures

Moveable Bridges and Wind Power Structures

Moveable bridges and Wind Power Structures offer unique advantages but also different challenges. Not only do they have structural properties to monitor, but also mechanical and electrical systems which must all work together to allow for proper system function. Monitoring of these integrated systems can be key to ensure continued function of these critical structures. Geocomp's iSiteCentral® has the ability to monitor these systems in parallel and pinpoint problems and deterioration mitigating risks to safety and functionality.

› Bridge Strikes

Bridge Strikes

Bridge strikes and impacts are a huge problem for structures. Both from over height vehicles as well as from ship and barge to pier collisions, bridge strikes can be devastating to a structure. Through looking at the deformations and vibrations as well as the recovery profile, Geocomp's systems can give real-time information about the safety of a structure following a collision.